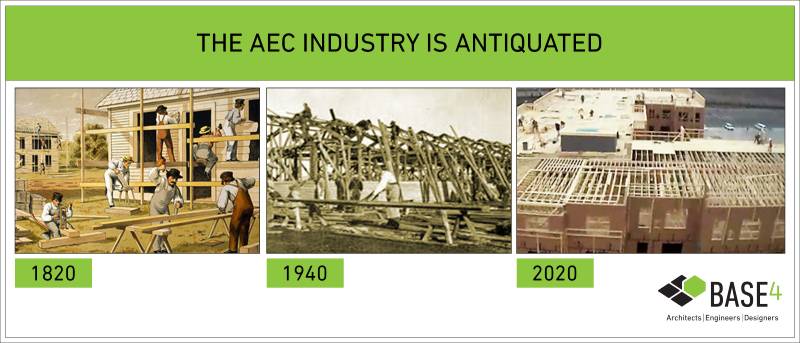

The world is changing, and we need to keep up! As the AEC industry is finding its “new normal,” industrialized construction (IC) is the way to go.

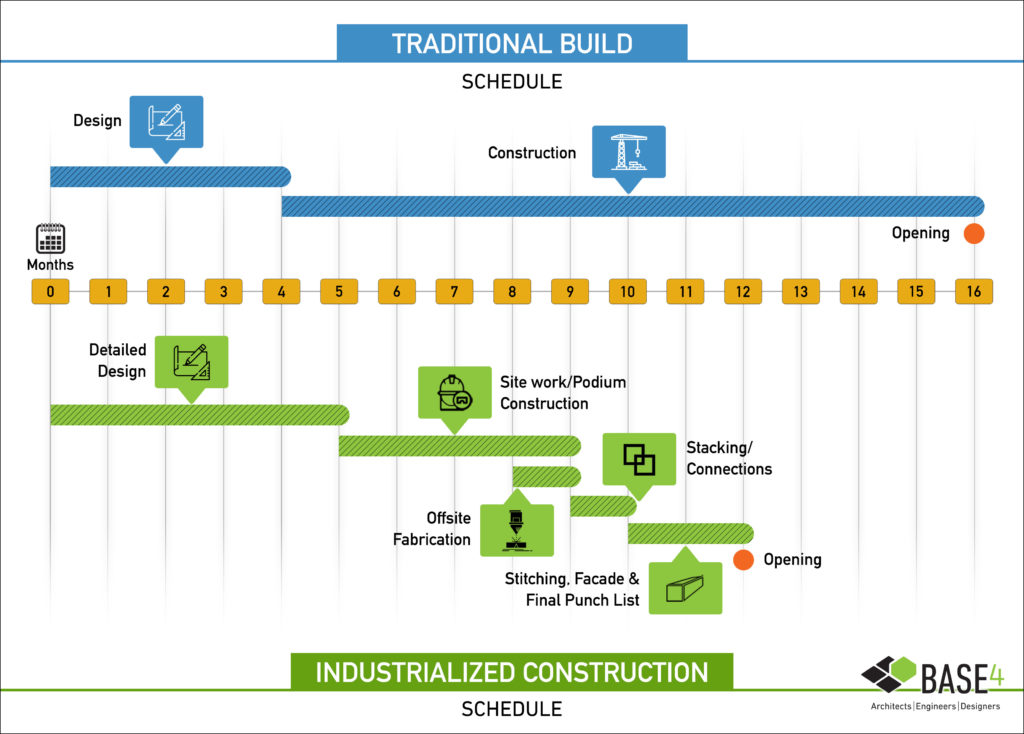

Multifamily developers who plan to build affordable housing will notice that the traditional build is too slow and unreliable right now.

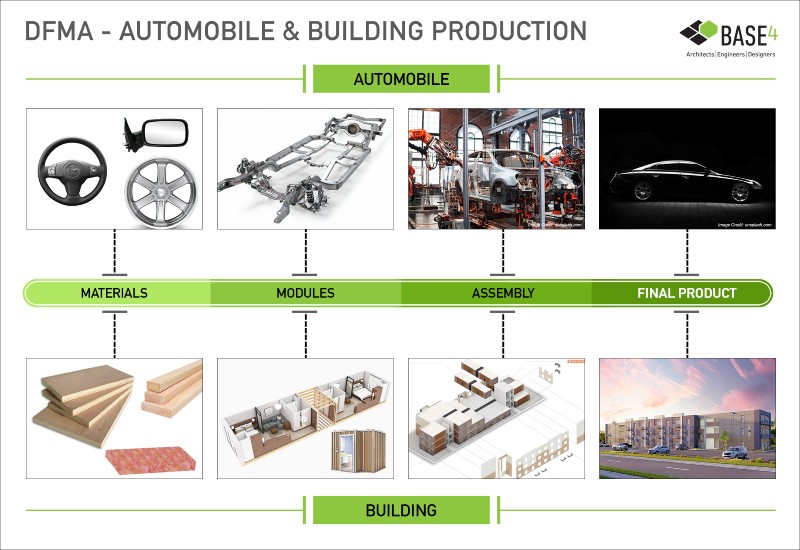

Imagine building without having to rely on the less-than-adequate tradesman to cut and install fittings at the jobsite, only to find out that it’s faulty—and repeating the process all over again with new material—modular and prefabricated construction can increase quality and efficiency for your next project.

- Volumetric modular is a process of stacking and connecting factory-finished whole module units to form a substantially complete building.

- It is a great way to build projects requiring many similar units, such as multifamily, student residence halls, hotels, office buildings, and apartments. Volumetric solutions are fully fitted-out units, which could constitute a room, or part of a room, that can be assembled onsite like a series of Lego bricks.

- Volumetric construction is also referred to as modular construction. These units can be made from most materials including light gauge steel frame, timber frame, concrete, and composites.

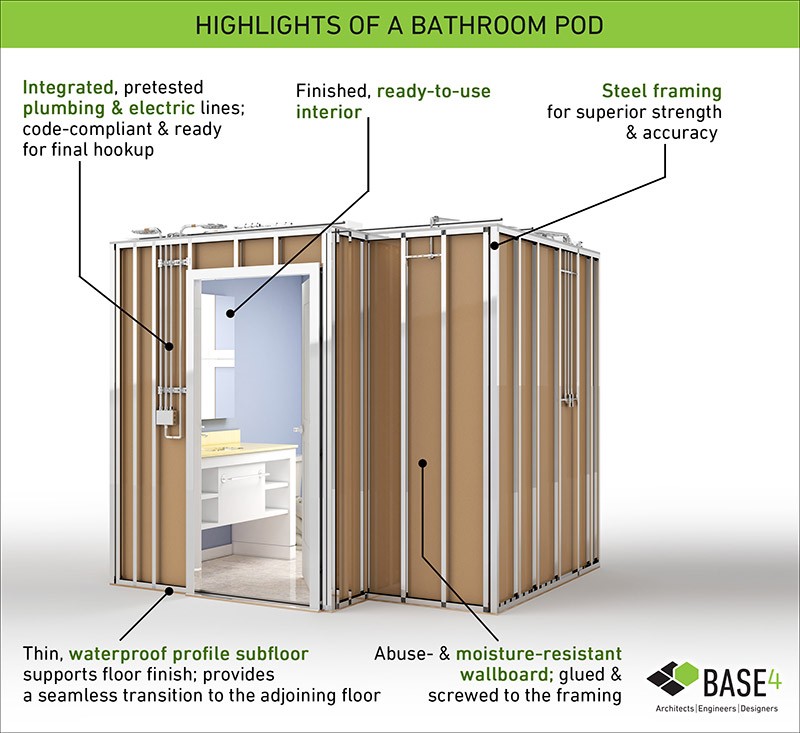

- Bathroom pods bring all the components of a bathroom—complete with finishes and MEP connections—in one finished and coordinated package.

- Pods are usually non-structural and used within a loadbearing structure. The enclosure can be of steel frame, timber frame, concrete or composite constructions.

- With traditional building, a multitude of trades needs to be organized to realize the bathroom design. Using bathroom pods lowers construction costs by reducing construction time, improving quality, and eliminating the bathroom defects list.

- Flat-panel units are built in a factory and later transported to the site to be assembled into a three-dimensional structure or to fit within an existing structure.

- The panels can be made of steel, timber construction materials, concrete, or masonry.

- Systems can include wall, floor, and roof panels to create the complete structural shell.

There are many different types of panel, with three main types:1

- Wooden Frame Panels: Timber-frame panels may be specified as open or closed panels. These panels are based on a structural framing system, which can have factory fitted windows, doors, MEP services, internal wall finishes, and external cladding.

- Cold-Formed Steel Panels (CFS): Similar to the Wooden Frame Panels – with CFS, the wooden framing members are replaced with thin steel sections. The steel sections used here are called cold-formed sections, meaning the sections are formed or given shape at room temperature.

- Structural insulated panels (SIPS): A sandwich structured composite, consisting of an insulating layer of rigid core sandwiched between two layers of structural board, used as a building material. The board can be sheet metal, plywood, cement, and polyurethane foam. SIPs are manufactured under factory-controlled conditions and can be custom-designed any project. They do not rely on internal studs for their structural performance.

Now you might be wondering if other components—like floors, roofs, and even elevator—can be fabricated in the same method as the Bathroom Pods and the answer is YES.

- Larger components can be incorporated into either conventionally built or Modern Methods of Construction (MMC) dwellings.

- Sub-assemblies and components can be added to existing brick and mortar buildings or those built using other MMC.2 They are parts that can be constructed off-site and constructed onsite.

Here are a few of the most common components that can be assembled offsite:

- Prefabricated foundations

- Floor/roof cassettes

- Prefabricated dormers

- Multi-trade racks

- Modular elevators

- Prepackaged Kits

- Stairs

At a modular factory assembly line

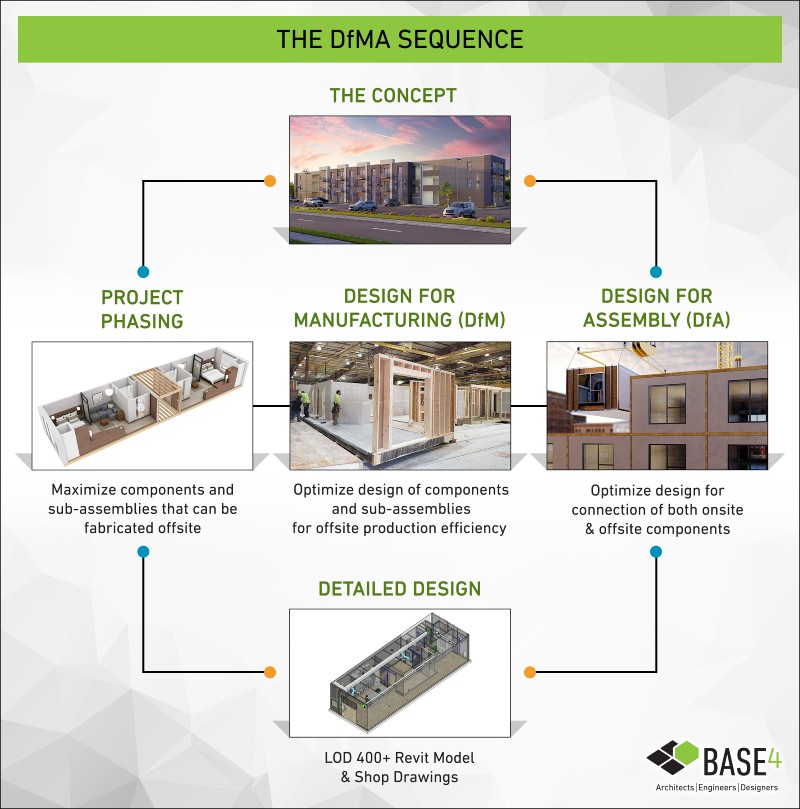

We at BASE4 have mastered the art and science of industrialized architecture–or DfMA. But more importantly, we realize the need for education. We aim to educate our industry for us to collectively reach the maximum potential and keep building better.

If you’re looking for ways to rethink construction, I invite you to reach out with your ideas and questions.