Everything You Asked About Modular, Answered

I’ve been asked hundreds of questions about modular construction over the few months. To make the information easily accessible, I compiled some of the most frequently asked questions for today’s newsletter. You might want to save this for future reference

1. Is modular right for my project?

We recommend the following determiners to discover whether your project is a good fit for modular.

- Can the bay widths of my units be accommodated with modular?

- Am I in a high-priced labor market?

- Am I in an urban environment where construction may be a major disruption?

- Do I want to fast-track the construction schedule for this project?

- Am I going to build a ground floor podium on my project even if I use traditional construction?

If you answered yes to any or all the questions above, modular could be a good fit.

2. Do I need a specific type of GC to build a modular project?

- This is not a requirement, but something we highly recommend.

- Modular projects have unique challenges compared to traditionally framed builds. Working with an experienced contractor will save you a great deal of time, money—and headaches.

- Modular construction is gaining traction but is still relatively new; with that comes likely setbacks. The entire project team, including the GC, subs, and design team, must have a team-focused approach to tackle potential issues early to avoid overall schedule delays.

3. When should I make the decision to go modular?

- The earlier the better. Modular projects require an entirely different design mindset and will be planned differently than a traditional project.

- It is thus important to discuss this with your A/E team early on.

- If the decision to go modular is made too far into the process, it is likely that any time saved by modular will be lost in redesign time.

4. Do I still need an architect and S/MEP engineer with modular?

- Architect and S/MEP engineering firms like Modz4 play an essential role in manufactured construction projects.

- We recommend hiring design firms familiar with offsite construction. Modular design demands sophisticated coordination by an experienced firm.

- A modular manufacturer prepares plans outlining the specific design of the modular boxes. However, it is the responsibility of the architect and engineers to take these plans, coordinate them with all the other disciplines, and design an overall structure that meets adopted building codes.

- They will also be responsible to act as the Architect and Engineer of Record for the entire building design.

5. I’ve designed a traditionally framed project. Should I choose to go modular, will I need a redesign?

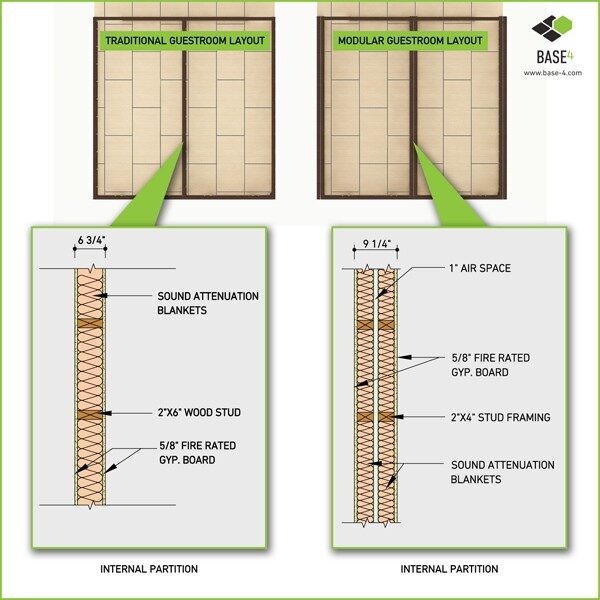

- Modular projects have double demising walls that typically increase the thickness between every unit bay, thus increasing the overall footprint.

- Also, modular units will be limited on the bay width, MEP configuration, and floor-to-floor heights, so these items must all be redesigned as well.

- If you are considering a modular project, you should make this decision early on to avoid lost time in redesign that would reduce time saved by adopting the modular model.

6. What types of modules are available in the market?

-

- You can choose from steel or wood modular units—based on your project needs.

- Steel modules are more sturdy and provide better stability for mid- to high-rise projects.

- Wood modules are comparatively lightweight and ideal for low-rises.

7. What is the cost of modular units?

- Cost varies greatly depending on the location, building use (e.g., hotels, dorms, apartments), and franchise, if applicable.

- The decision to use wood or steel also determines cost.

- Right now, wood modular construction is—for the most part—cost neutral with traditionally wood-framed podium construction.

- We recommend reaching out to the modular manufacturers early on as they can provide you with general budgeting numbers specific to your project.

8. Does my financing structure need to change for a modular project?

- In contrast to typical construction, 60−70% of your entire construction cost to purchase the modules is needed up front. This is much different than a traditional construction loan draw, and many lenders will need to be educated on this process.

- It’s wise to involve your lender during the initial phase if you are considering going modular. Some lenders might need some time to figure out how this will change the lending terms

9. How does modular construction shorten my project timeline?

- Modular units can be produced as the foundation and podium work are taking place at the site.

- As a result, modular construction can typically reduce build-time for a standard 4- to 5-story, 100-unit building, by three to six months when compared to traditional construction methods.

- With that said, it may vary greatly depending on the specific project program and site conditions.

10. Where do I ship my FF&E for a modular project?

- All FF&E must be delivered before the modular factory starts unit production.

- Proper planning is crucial since FF&E deliveries can take significant time, and late deliveries may hamper the project schedule.

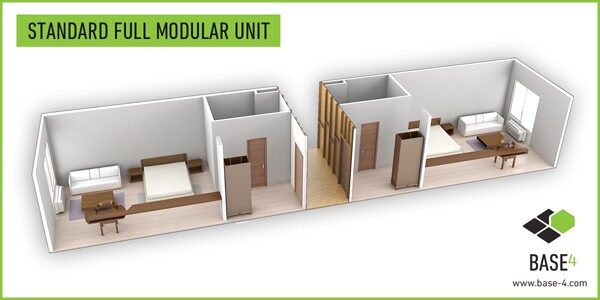

11. What does a standard full modular unit look like?

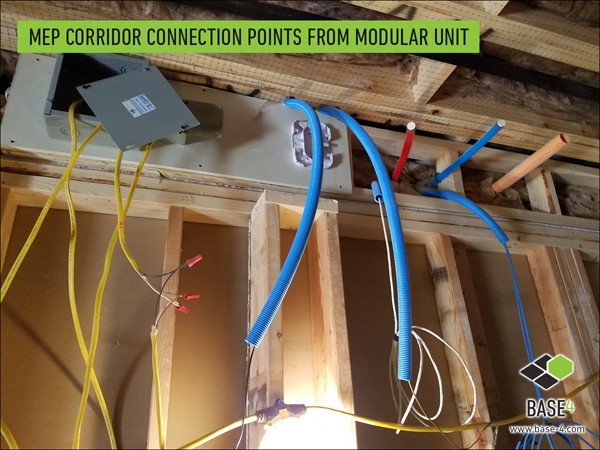

- A standard modular unit includes two room-units separated by a corridor. Each module’s MEP connections are made through the corridor. At this stage, paint and finishes are complete in the units, but the corridor is left unfinished with plywood flooring and open stud walls.

- Other configurations, including single bays, can be fabricated as well.

- Modular manufacturers usually design and equip individual modules with all necessary items, including everything down to the bed mattress.

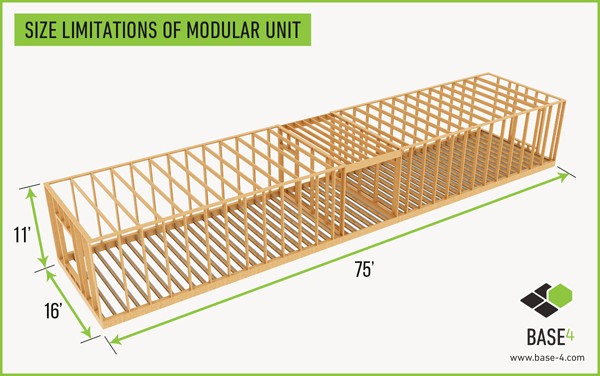

12. What are the limitations of modular?

- Modular units have a strict size limitation. Due to shipping constraints, each unit cannot be more than 14 to 16 feet wide, 60 to 75 feet long, and 11 feet high.

- For larger room-units, multiple modules can be set side-by-side to achieve the desired area.

- However, modular might not work for you if your project requires higher than 11-foot ceiling.

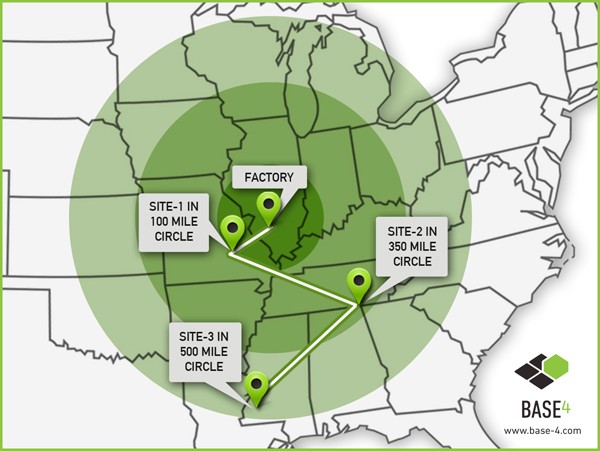

13. How far do modular companies ship from their plant to my site?

- Most modular building units are shipped from within a 500-mileradius of the construction site, although shipping distance is determined by the complexity of the project.

- Some manufacturers will go farther when it makes sense for the project.

- Many manufacturers also ship overseas via vessels.

14. What do modular units look like when they arrive at the site?

- Delivered module units are assembled as large volumetric components, wrapped in plastic for temporary protection from inclement weather and damage.

- The modules truck in to the site, as shown below:

15. What work needs to be done once the modular units arrive on site?

- Arrived modular units are lifted by a crane and set on the already constructed first floor podium.

- Then the final installation of electrical, plumbing, mechanical, and structural connections occur in the corridor.

- To avoid any damage at this point of construction, every unit is locked, and on-site staff are not allowed in the room-units.

16. Can I place modular units directly on the ground floor slab?

- Typically, modular units are placed on a traditionally framed ground floor steel or concrete podium structure and start at the second floor rather than directly on a ground floor slab.

- This configuration allows access to the bottom of the modular units after they are set.

17. How many modular units can I set in a day?

- This is highly project- and weather-dependent.

- Ideally, modular companies aim to set 12 units per day on a 4-story project.

- Wood modules must be set in multiples of the number of stories of modular units. (i.e., with a 4-story project, they will set 4, 8, or 12 units per day). This is to avoid leaving a non-roof module exposed to the elements.

18. What type of quality of finishes should I expect from a modular project?

- Modules are produced in a controlled environment by specialized members in a specific trade.

- Each person on the assembly line consistently delivers high-quality products in accordance with developed standards.

- As I mentioned above, only corridors require finishing work at the project site.

- As a result, modules have a higher level of precision and consistency than you will see with a traditionally built project.

19. How are local inspections handled?

- The modular approach reduces the number of local inspections from a traditional project.

- Inspections of the modular units must be completed at the factory when visualization of the inside of the unit is still possible.

- Most modular companies will handle this as part of their fabrication contract and will have the modular units stamped for the specific state approval to which they are being delivered.

- Once a modular unit arrives on site, local inspectors have no jurisdiction over the actual units themselves. However, local inspectors will still be responsible for many aspects of a project (e.g., ground floor areas, corridors, etc.).

- Educating local inspectors about jurisdiction authority over the room-units is important.

I hope you find this newsletter helpful and welcome your questions and comments!

Thank you,

Blair Hildahl

Modz4 Principal

608.304.5228

BlairH@base-4.com