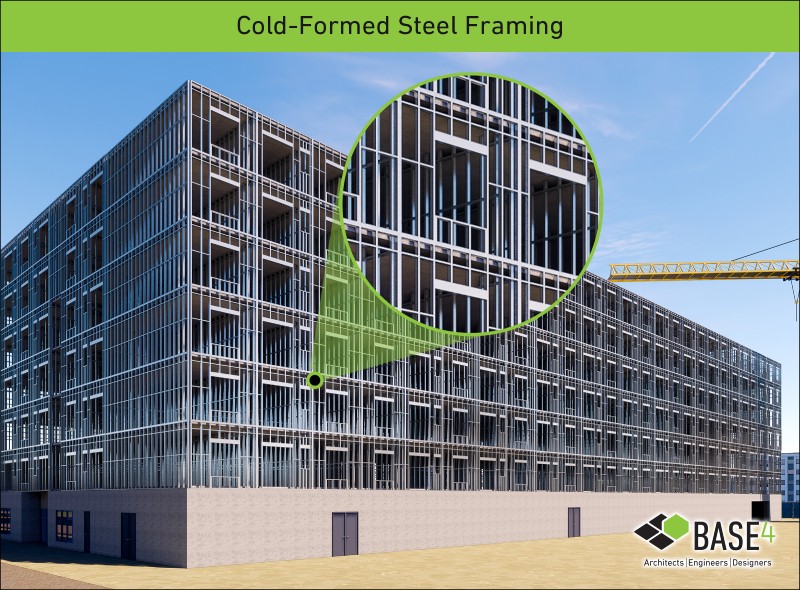

We’ve recently discussed cold-formed steel and how it can be utilized with Industrialized Construction. With lumber prices soaring, developers are looking for steel solutions. The term “Steel” is one of those broad terms that gets thrown around a lot. Today we are going to take a deep dive into what we mean when we say “Cold-Formed Steel”.

NOT ALL STEEL IS THE SAME

Steel has an outstanding strength-to-weight ratio and flexes with force, which is why it’s frequently used for large construction projects like high-rise buildings. When using steel framing, there are two main options to consider: Cold-Formed Steel and Structural Steel. They are very different in both production and framing methods.

- Cold-Formed Steel (CFS)—also called Light Gauge Steel or metal studs—is cold-formed into “C” or “Z” shaped members, capable of holding heavy loads. “Cold-Formed” means the sections are shaped at room temperature by guiding the steel through a series of rollers.

These light-framed steel members are similar to wood-framed construction in principle. These thin members are used to frame out walls, floors, and roof systems in much the same way as 2x wood studs. Due to their strength, light gauge steel also requires fewer studs because they can be placed further apart. In general, light gauge will produce less waste, which is more environmentally friendly and cost-effective than wood alternatives.

- Structural Steel is hot rolled, much thicker, and considerably stronger and heavier. “Hot-rolled” means the member is shaped while the steel is molten hot. Structural steel projects are framed out with heavy, large members and used for framing out large open spaces and buildings, bridges, and industrial sites.

Used in conjunction with concrete, the most durable structures employ structural steel. Because it is thicker and heavier than light gauge steel, the best fastening methods employ welding, bolting, or riveting.

This is what most people envision when they hear “steel framing”.

This is what most people envision when they hear “steel framing”.

WHY THE CONFUSION

It is very common to have CFS and Structural Steel framing on the same project. This complicates things a bit. For typical apartment projects, both CFS and Structural Steel can be used to your advantage. Here’s how:

- The ground floor podium is framed out with structural steel to accommodate the large open areas that are on the ground floor for amenity space.

- The unit floors above are then framed out with cold-formed steel and make up the tower.

When talking about Industrialized Construction (IC), we primarily are focused on the former, CFS framing, as this type of construction results in members that can be easily cut and shaped to specific project needs and are light enough for easy transportation from factories to project sites.

A DEEPER DIVE INTO CFS

Cold-formed steel framing is outperforming wood framing in the construction industry right now.

The pandemic is upsetting global supply chains in every industry—especially the construction industry.

Staying on the cutting-edge of the building market is hard, especially with the rapid onset of industrialized construction (IC).

It’s time to consider CFS as an ideal option for your next project! Please don’t hesitate to contact us if you have any questions about design solutions for today’s changing market. And don’t forget to check out STONEPILE llc—our higher education solution for today’s emerging construction leaders.

Thank you,

Blair Hildahl

BASE4 Principal

608.304.5228

BlairH@base-4.com

![]()