Building Modular for Low- to Mid-Rise Structures: Next Steps

Let’s assume you’ve decided to go modular with your next project. Now what? This third article in our series on modular explains your next steps.

After choosing to go modular, you must decide whether to use wood or steel modular boxes. Typically, hotels of 4-5 stories in height utilize wood boxes. In this article, I discuss modular know-how when using wood. Next week’s newsletter will detail steel modular considerations, which can be a better fit for higher structures.

Once you choose your AEC team and modular manufacturer, you’ll want to know what happens next. As an informed owner/developer, you want to know about the projected timelines, jobsite and modular factory processes, and what happens after your modular boxes arrive on site.

So, here we go! Jump directly to a question:

What does a standard, full wood modular box look like?

What are the dimensions of a typical wood module?

What type of quality of finishes should I expect from a modular project?

How far do modular companies ship from their plant to my site?

My projects are spread across multiple regions. Do I have to choose new teams for each?

Where and when do I ship my FF&E for a modular project?

Who is accountable for quality and deadlines? Who coordinates with the manufacturer?

What do modular boxes look like when they arrive at the site?

What happens once the modular boxes arrive on site?

Can I place modules directly on the ground floor slab?

How many modular boxes can I set in a day?

How are local inspections handled?

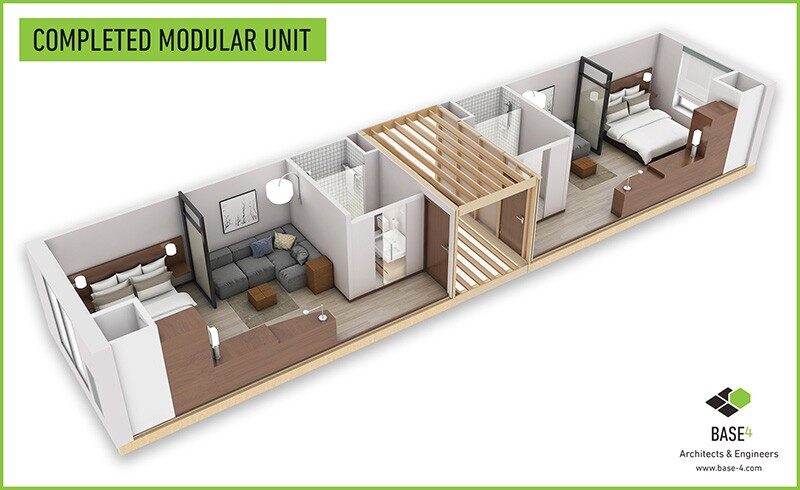

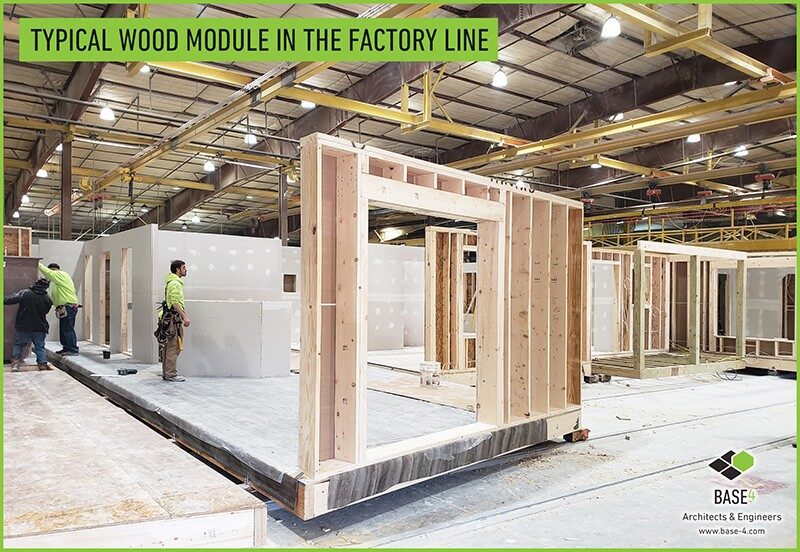

What does a standard, full wood modular box look like?

- A standard wood modular box includes two room-units separated by a corridor. Each module’s MEP connections are made through the corridor. At this stage, guestroom units are fully furnished with paint and furniture but the corridor is left unfinished with plywood flooring and open stud walls.

- Other configurations—including single bays—can be fabricated as well.

- Modular manufacturers usually design and equip individual modules with all necessary items, including everything down to the bed mattress.

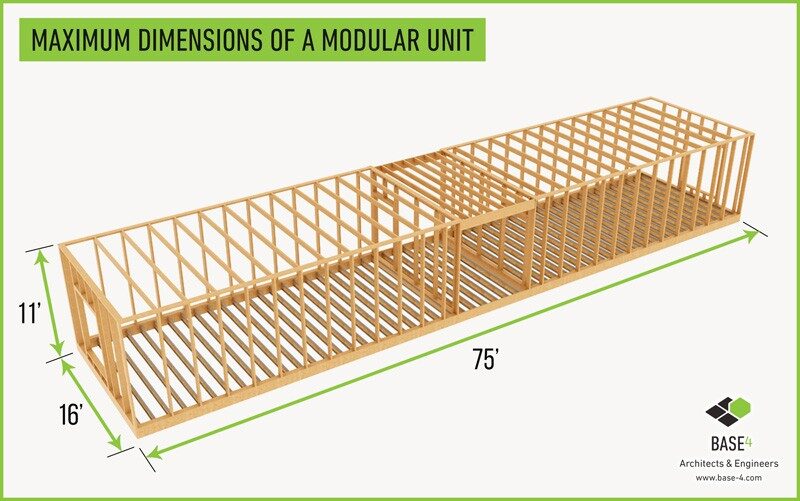

What are the dimensions of a typical wood module?

- Modular boxes have a strict size limitation. Due to shipping constraints, each module cannot be more than 14 to 16 feet wide, 60 to 75 feet long, and 11 feet high.

- For larger room-units, multiple modules can be set side-by-side to achieve the desired area. However, this “box-cut” configuration requires extra work in the field.

- Please note that modular might not work for you if your project requires higher than an 11-foot ceiling.

What type of quality of finishes should I expect from a modular project?

- Modules are produced in a controlled environment by specialized members for specific trades.

- Each person on the assembly line consistently delivers high-quality products in accordance with developed standards.

- Only the corridors and lobby require finishing work at the project site.

- As a result, modules have a higher level of precision and consistency than you will see with a traditionally built project.

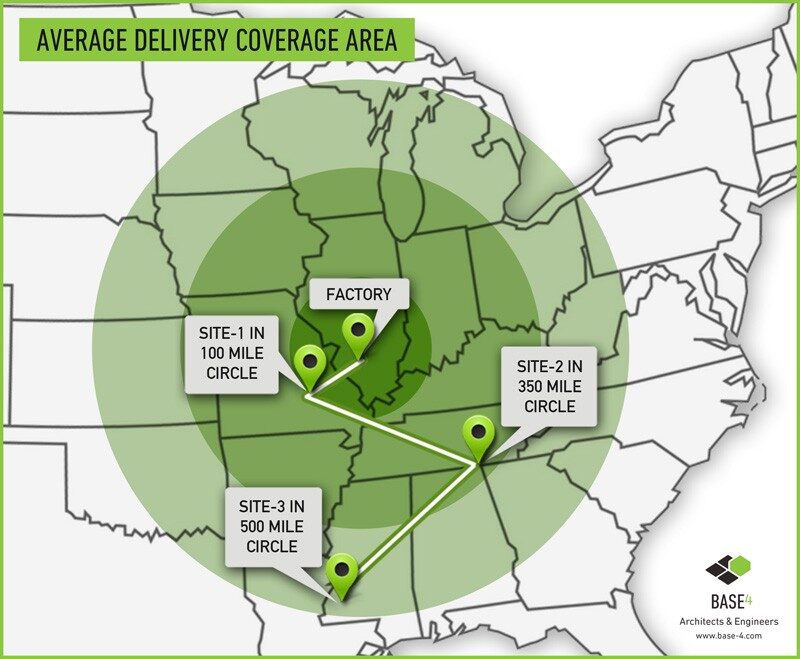

How far do modular companies ship from their plant to my site?

- Most modular building boxes are shipped from within a 500-mile radius of the construction site, although shipping distance is determined by the complexity of the project.

- Shipping distance is often driven by cost considerations, so there is a certain distance that makes shipping unfeasible.

- Some manufacturers will go farther when it makes sense for the project, so discussion with your modular manufacturer is important.

My projects are spread across multiple regions. Do I have to choose new teams for each?

- As long as your modular production factory is in a 500-mile radius, you can use the same teams on multiple projects.

- However, for the actual hotel design, your architects and engineers of record need to have licensure to practice in the state of your project. As noted last week, your design team’s relationships with local authorities go a long way.

- Specialized and experienced hotel design firms like Base4 and Modz4 have extensive reach in all 50 states, making your move to modular much easier. Our AEC project managers maintain smooth coordination between your modular partners, local authorities, and onsite contractors.

Where and when do I ship my FF&E for a modular project?

- All FF&E must be delivered at the modular factory before it starts production.

- Proper planning is crucial since FF&E deliveries can take significant time, and late deliveries may hamper the project schedule.

Who is accountable for quality and deadlines? Who coordinates with the manufacturer?

- The modular manufacturer directs the timelines on the module production and delivery. They also handle shop drawings and strategize the delivery, storage, and craning logistics.

- Your AEC team designs, engineers, and coordinates the bigger picture items, including structural components, foundation, lobby areas, corridors, MEP connections, and overall finalization of the project after the modules are delivered.

- Seamless coordination requires sophisticated team efforts.

What do modular boxes look like when they arrive at the site?

- Delivered module boxes are assembled as large volumetric components, wrapped in plastic for temporary protection from inclement weather and damage.

- The modules truck to the site, as shown below:

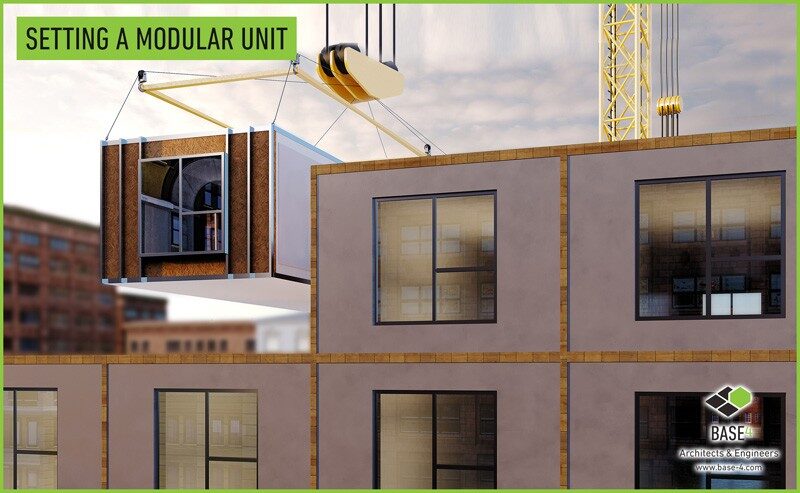

What happens once the modular boxes arrive on site?

- The trucks arriving on site unload each unit and set it on cribbing, to free the trucks and avoid vehicle jamming at the site.

- The crane then lifts each unit from the cribbing and places it on either the already constructed first floor podium or a crawlspace.

- The construction crew makes final installations of electrical, plumbing, mechanical, and structural connections, generally in the corridor.

- To avoid any damage at this point of construction, every unit is locked, and on-site staff are not allowed in the room-units.

Can I place modules directly on the ground floor slab?

- Typically, modular boxes are placed either on a podium or over a crawlspace.

- This configuration allows access to the bottom of the units after they are set.

- When stacking on a traditionally framed ground floor steel or concrete podium structure, the modular units start at the second floor rather than directly on a ground floor slab.

How many modular boxes can I set in a day?

- This is heavily project- and weather-dependent.

- Ideally, modular companies aim to set 12 boxes per day on a 4-story project.

- Wood modules must be set in multiples of the number of stories. (i.e., for a 4-story project, four, eight, or 12 modules are set per day). Doing so avoids leaving a module without a roof and exposed to outer elements.

How are local inspections handled?

- The modular approach reduces the number of local inspections from a traditional project.

- Inspections of the modular boxes must be completed at the factory when inside access and amendments are still possible.

- Most modular companies will handle this as part of their fabrication contract and will have the modular boxes stamped for the specific state approval to which they are being delivered.

- Once a module arrives on site, local inspectors have no jurisdiction over the actual units themselves. However, the inspectors will still be responsible for many aspects of a project—such as ground floor areas and corridors, among others.

- Educating local inspectors about jurisdiction authority over the room-units is important.

Now that we are in the third week of our modular series, you likely have an overall understanding of the workings of modular. I have been getting many emails with great questions. Keep them coming, and I’ll respond with specific answers and possibilities.

Next week, I address some of these questions for steel modular units for mid- to high-rise construction. But for now, make sure to sign up for our Modz4 newsletters!

Check out these designs!